Chapter 2.3

Protective Measures

When faced with a potential hazard, machine designers must find a solution that is safe, functional, efficient, and affordable. It may seem difficult, but success comes from focusing on two main targets: safety and practicality.

To succeed, there are two things you should do

1: Follow an 'ALARP' approach

Effort should be As Low As Reasonably Possible (ALARP)

2: Follow the three basic rules of industrial safety

Rule 1: Guarding - Lock the hazard in or the people out

If there is a hazard from a moving part, hot surfaces, or electric discharge by contact, never allow people to contact the hazard involuntarily.

That is:

- Do not allow hazardous moving parts to run unprotected.

- Do not allow hot surfaces and live parts to be accidentally touched.

Rule 2: Monitoring and interlocking - Use sensors and control systems to stop the movement or hazard before an accident can occur.

If the first rule cannot be followed, monitor the time in which people could contact the hazard source

End the hazard before the person can encounter it by:

- Using sensors like light barriers, laser scanners, camera systems, contact mats, ultrasound and infrared sensors to detect a person approaching

- Stopping the moving part or ending the hazard.

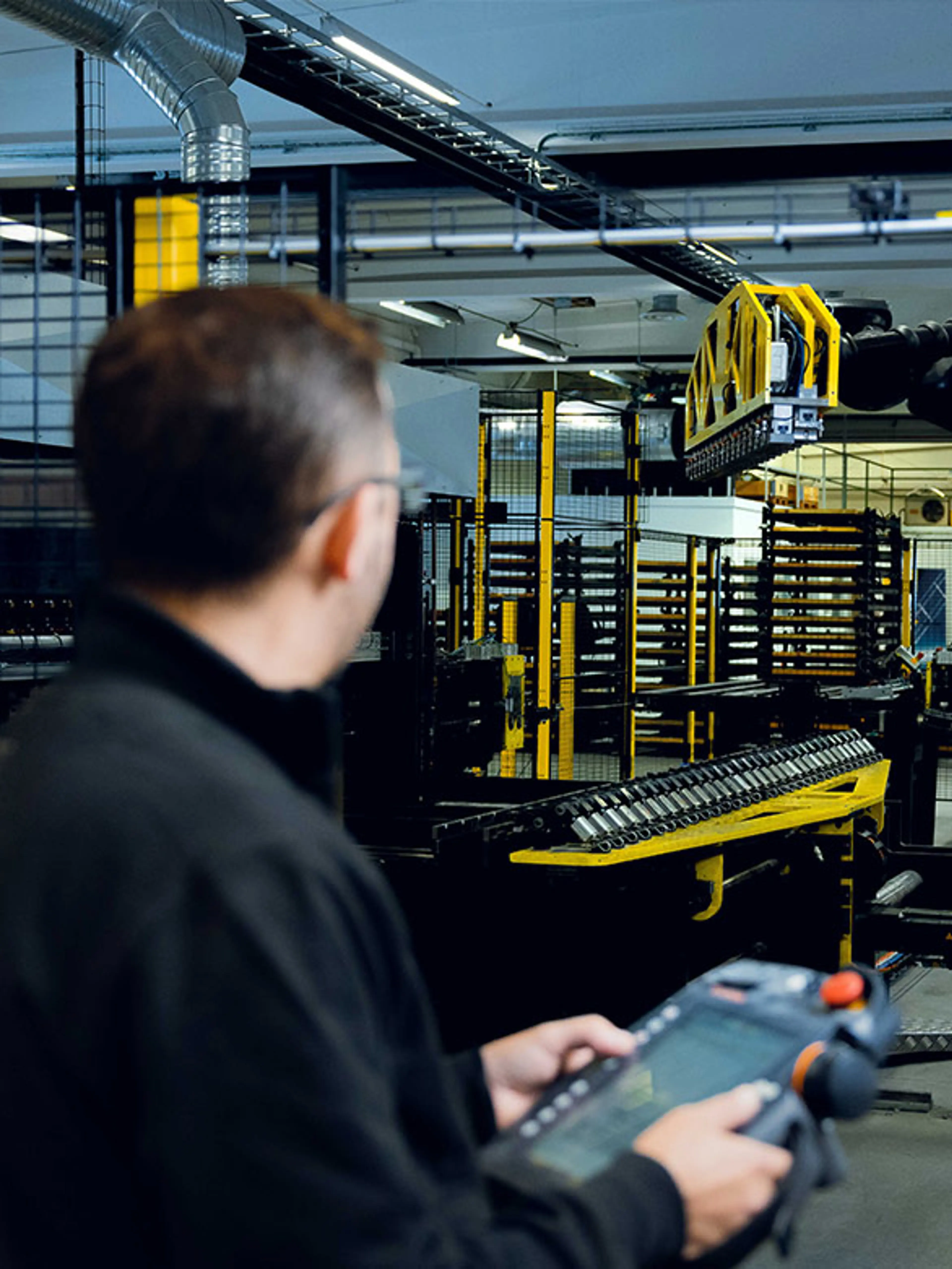

Rule 3: Manual control - make the person aware and in control of the hazard.

If the first and second rules cannot be followed, make the person control the potential hazard and ensure capability of stopping the hazard in time..

That is:

- The operator must actively press buttons to start and continue a hazardous situation.

- Place the button(s) outside the hazard area or at a safe distance

- Reduce the operating speed so the person can still react and let go of the controls.